Be it any road vehicle, industrial machine and equipment, or a marine vessel; our workshop is equipped with state-of-the-art test equipment and highly trained specialists to service, diagnose and repair your turbochargers.

Our turbocharger service solutions include OEM spare parts including Melett and Jrone and a range of high-quality aftermarket parts.

We are equipped with a TurboClinic TC Workbench; a unique equipment that integrates all that is needed to repair a turbocharger – right from balancing to the adjustment of nozzle vanes, and from test of cartridges for oil leaks to the test of electronic actuators and the actuator’s programming. It goes a step further in measuring the efficiency of the compressor. Bottom line, it gives us 100% precision for the repair of your turbochargers.

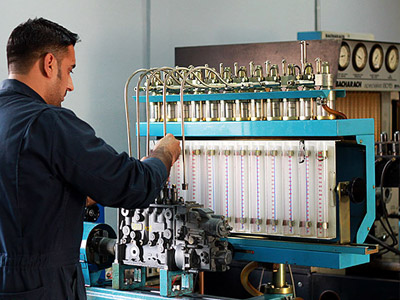

The equipment we use to test your diesel fuel injectors and pumps helps us make an informed decision about the best repair solution for your diesel engine. Our goal is to extend the life of your diesel engine and avoid costly downtime for your business.

Our equipment provides us the most efficient and precise way to examine modern-high-pressure fuel components.

The equipment we use are:

We advise on the best service for you after we complete a detailed inspection of your failed pump, part of turbo. If your item is badly worn or damaged, then a repair is not the practical solution.

We diagnose the problem onsite. If the fuel pump or injector has an issue, we bring it in for repair and after repair testing.

Diagnostic tools we have:

Engine manufacturers are switching to Direct Injection to meet emissions standards, better performance and greater fuel economy. GDI or Gasoline Direct Injection is the way forward. We test all types of Gasoline injectors including High-Pressure gasoline injectors.

The equipment we use for testing Gasoline injectors:

We advise on the best service for you after we complete a detailed inspection of your failed pump, part of turbo. If your item is badly worn or damaged, then a repair is not the practical solution.

With us, you have two options:

By rebuild / reconditioned we mean, the item is completely stripped to each of its components. All worn parts are scrapped and replaced with new replacement parts. Once all parts being reused are confirmed to be in good condition, and worn parts are disposed and replaced, rebuilding can commence, including balancing and calibration, resulting in a newly reconditioned item.